Artwork Requirements & Branding Methods

Select below to jump to a specific section:

Spot Colour & Full Colour

It's a topic that can cause a great deal of confusion, but understanding the difference between spot colour and full colour artwork can help you to achieve a more accurate quote for your branded merchandise.

Spot Colour

A spot colour is any colour generated by an ink (pure or mixed) that is printed using a single run - or 100% of a specific Pantone. More simply put, spot colour artwork is made up of solid colours; colours not broken by effects.

Full Colour

Further details regarding 'Full Colour Printing' as opposed to 'Four Colour Printing' can be found here. We can always check your artwork to confirm what's possible, but it's best to have an understanding prior to requesting a quotation.

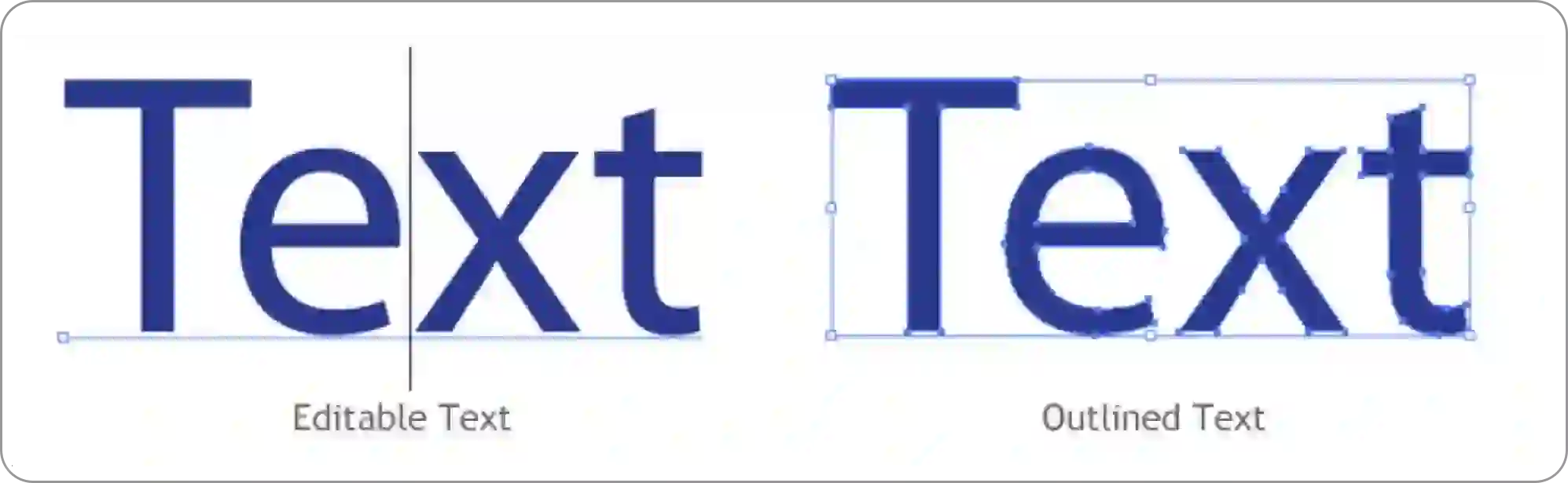

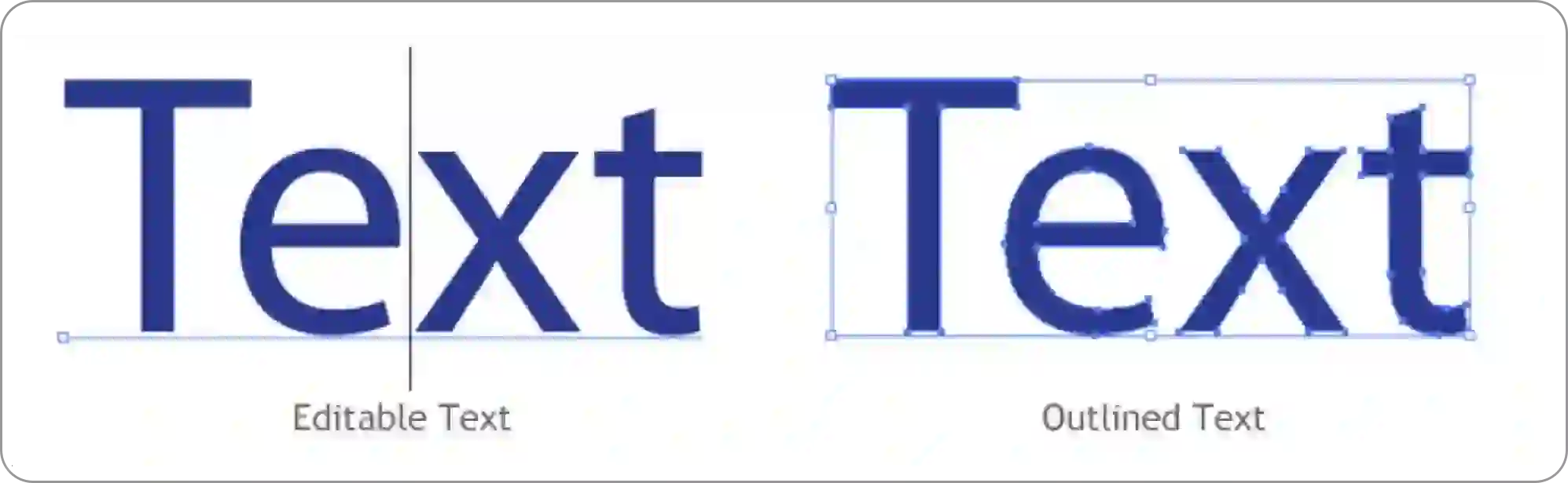

Fonts & Outlining

In a perfect world, all artwork supplied to us will have any text outlined. This means that the text has been converted into a vector representation of the words, rather than editable text.

The reason for this is that not all computers contain the same fonts - we may not have the same font that is used in your artwork - so the artwork wouldn't appear correctly on our systems. So, we'll need to have the artwork supplied in a vector image format. We can then see what it is meant to look like, and proceed with creating your visual.

File Types

An image isn’t always just an image. To make sure we can work with your artwork effectively, we need to make sure that it’s in the right format. Here’s a breakdown of the main types of image that we can work with - and when we can work with them.

Vector Images

Vector images are ‘drawn’ using mathematical points on an x and y axis. These points are joined by lines, which form the outline of a shape.

Scaling these images simply relocates the points used to calculate how the image is shown, so they can be made larger or smaller without losing any detail - to whatever size you need!

Examples of file formats that can contain vector images include .pdf, .ai, and .eps.

Raster Images

Raster images (or sometimes called bitmap images) are made up of loads of tiny squares of colour called pixels.

When increased in size (to cover a large print area, for example), the pixels are also made larger. This makes the image lose detail, and it becomes 'pixellated'. This is why raster/bitmap images need to be of a high resolution - at least 300dpi (dots per inch).

Examples of raster/bitmap file formats include .jpg, .png and .bmp.

If you need your artwork in vector format so it can become scalable, but don’t have access to it - don’t worry. We can get it sorted for you. We’ll redraw your artwork in vector format. Depending on how complex this is to do, there may be a small charge for this service - but we’ll always check with you before proceeding.

Print & Branding Methods

Digital Printing

Digital printing is the reproduction of digital images on a physical surface, such as common or photographic paper, cardboard, film, cloth, plastic, vinyl, magnets, or labels. All are possible with various desktop and industrial sized printers.

The process allows for blends of colour and tone within your designs instead of resorting to individual flat, solid colours. It’s made up by a combination of cyan, magenta, yellow and black inks (called CMYK), which combine to create the colours you need.

Here’s the thing - digital printing requires an image resolution of at least 300dpi (that’s dots per inch). Anything less than that will result in a poor quality print, and won’t be allowed.

Wanna know the difference between pad printing and screen printing - and what that means for your artwork - but don't know where to start? Check out this handy guide to some of the most popular branding methods available in the industry…

Litho Printing

In much the same way as digital printing, litho printing gets full colour prints onto various physical surfaces. Litho printing enables you to personalise many desktop promotional products where large multiple runs are necessary.

Again, high resolution artwork is needed for this process (a minimum of 300dpi).

Engraving

Engraving is a process that requires the incising of a design onto a hard, usually flat surface, by cutting grooves into it. Back in the day, this process was originally done by hand - but now it can be performed using lasers when branding large quantities of promotional products. This process doesn’t usually allow for colour, instead relying on the colour of the product itself to show through.

Screen Printing

Screen Printing is a printmaking process based on the creation of individual screens - one for each colour present in a piece of artwork.

Artwork for Screen Printing ideally needs to consist of vector images and outlined text so that each piece of colour can be separated. Each screen made then acts as a layer, with each layer printed in order to build up a complete image.

Vinyl Skins

Skins are an innovative product, and skins4things skins are made in the UK utilising the latest material, printing and cutting technology. They’re made from premium patented 3MTM adhesive vinyl, and utilise high quality printing using a 4 colour process. Images can also be photographic or vector art.

Skins are laminated to lock in the colour and protect the device from everyday scuffs and scrapes. They’re precision cut for individual devices as well, so they follow the unique contours of each device - creating a second skin. Skins are very easy for you or your customers to apply, with no risk of creases or air bubbles.

And importantly, skins are easy to take off. They just peel off leaving no residue or marks on the device.

Embossing

Embossing is a process that creates an impression of a design onto a surface that allows for marks to remain once the pressure is released.

There are 2 typical varieties of embossing: blind embossing, where the design will remain the colour of the product it's being embossed on - and foil blocking - when (once a design is embossed) it's filled with a metallic paint such as gold or silver. Shiny!

Transfer Printing

Transfer printing is a method of applying an image to a curved or uneven surface. It is most commonly used for printing onto porcelain, but can also be applied to various other surfaces, like cloth.

Transfer printing allows for designs to include complete digital images (like full colour photography) along with vector and/or high resolution bitmap images, which can then be applied to a number of different products.

Embroidery

The process of embroidery allows for artwork to be recreated by decorating fabric or other materials with designs stitched in strands of thread or yarn using a needle - we use specialist equipment for mass production.

Feel free to provide Pantone references, but embroiderers use a slightly different colour code based on the threads used, so colours can only be matched as closely as possible. It's best to avoid blends of colour when creating an embroidery and stick to using solid colours.

Moulding

Moulding is a process used for products that require the use of various materials to make bespoke items. Soft PVC and recycled plastic, for example, can be set within custom moulds to produce various products.

This process can only be achieved successfully with vector-based artwork.

Pad Printing

Traditionally called tampography or tampo printing, pad printing allows 2D images to be printed onto curved surfaces or 3D objects. It involves using a rubber silicone pad to collect ink from an etched plate and transferring it to the product.

Pad printing is ideal for all kinds of promotional merchandise uses, because it allows many 3D product surfaces to be branded - which wouldn’t otherwise be possible with printing methods such as screen printing.

Pantone Reference

Pantone is a colour matching system universally used by many industries, not least the promotional products industry. It allows designers to match specific colours (your brand colours, for example) regardless of the process used to reproduce the colour, and allows brands such as yours to assign an exact colour reference to those used.

Click the button below to head on over to Pantone’s website and find your brand colours...